Linear actuators are electric motors used primarily in cranes and other heavy industry applications. They provide high torque and precise speed control, making them ideal for demanding lifting tasks and material handling. The durable and efficient designs of linear actuators ensure reliable operation in challenging conditions. These motors are widely used in ports, construction sites, and industrial facilities where high lifting capacity and precise motion control are required.

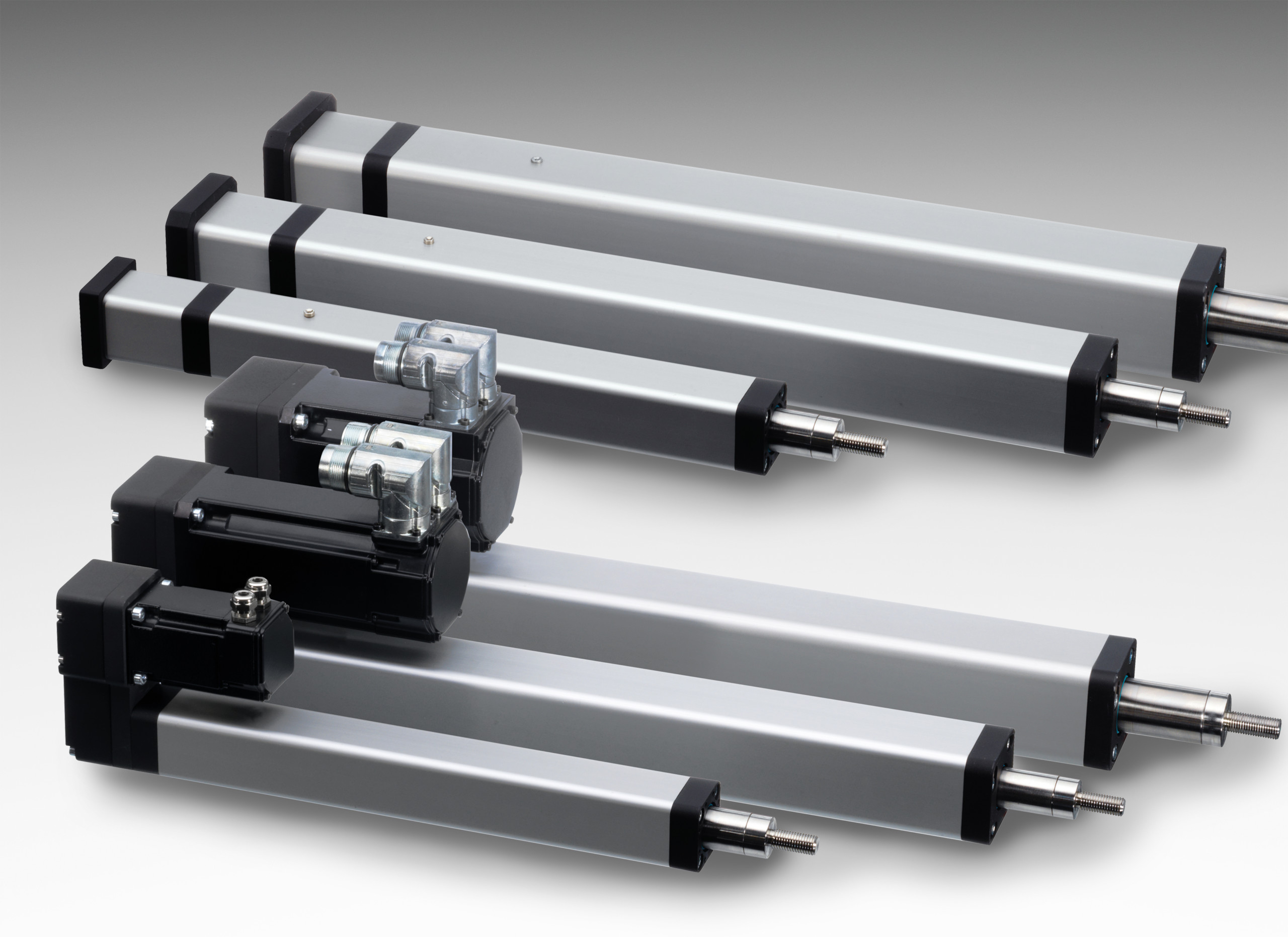

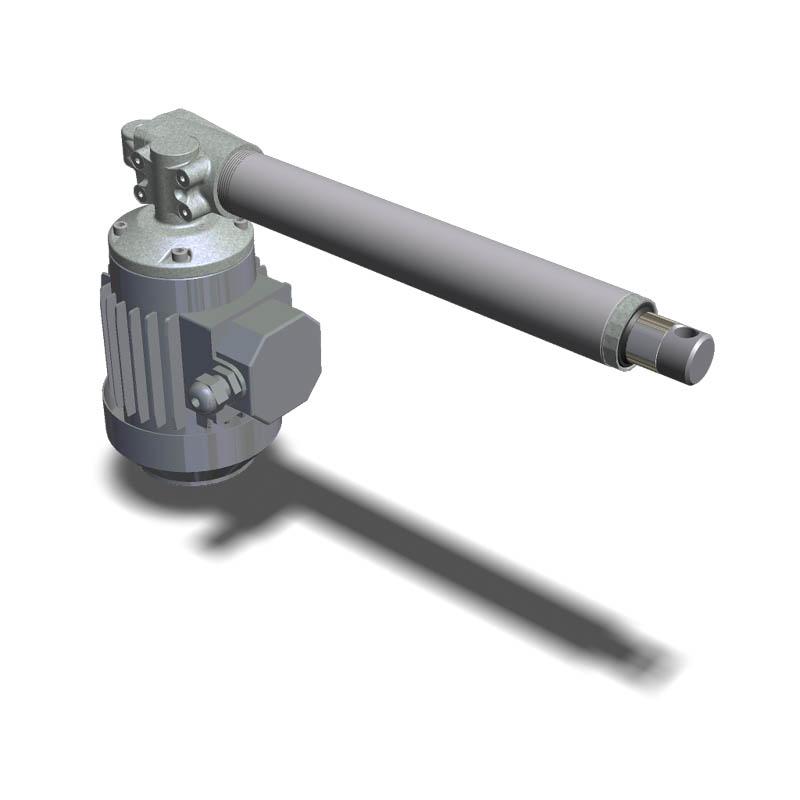

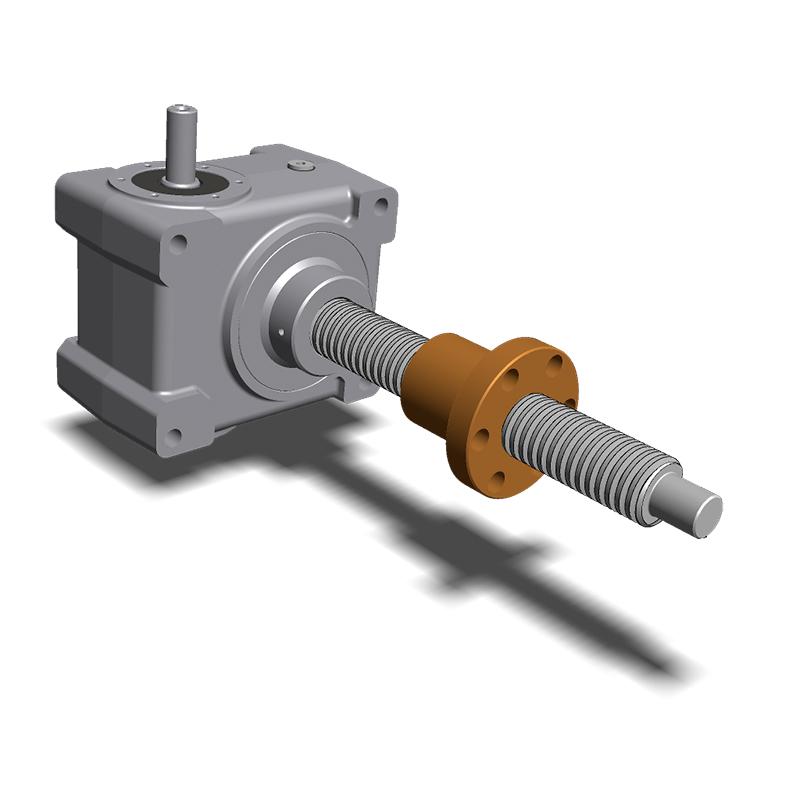

With a linear actuator, linear movements can be easily implemented. We offer a wide range of stroke lengths, available in either ball screw or trapezoidal screw versions. Linear actuators are a cost-effective alternative to replace pneumatic cylinders and hydraulics in various applications. Common features of linear actuators include easy installation, maintenance-free operation, controllable and precise movement, and energy efficiency.