Product menu

- Aluminium profile systems

- Assembly & Robotics

- Axial Shaft Couplings & Torque limiters

- Ball Bearing Screws

- Cable carriers

- Gas springs & shock absorbers, air springs

- Gearheads

- Guideway protection

-

Industrial IT

- Cellular Gateways/Routers

- Controllers & I/Os

- Ethernet Media Converters

- Ethernet switches

- Industrial computers

- Industrial Cybersecurity

- Industrial displays & panel computers

- Protocol Gateways

- Secure Routers & Remote Access

- Serial Converters

- Serial Device Servers

- Software

- USB-to-Serial Converters/USB Hubs

- Wireless AP/Bridge/Client

- Lifting columns & ergonomy solutions

- Linear actuators

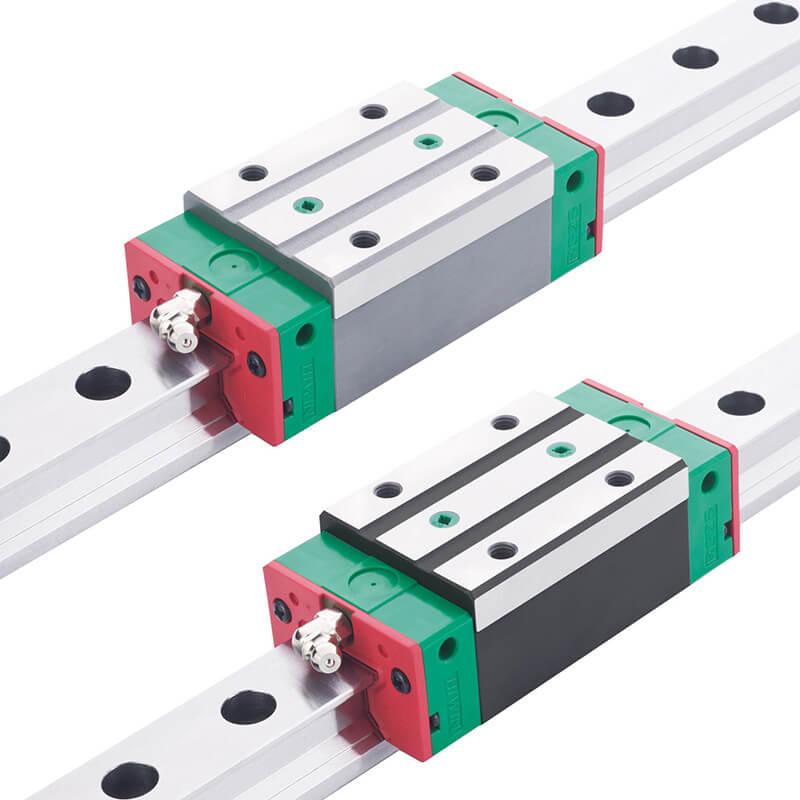

- Linear guideways

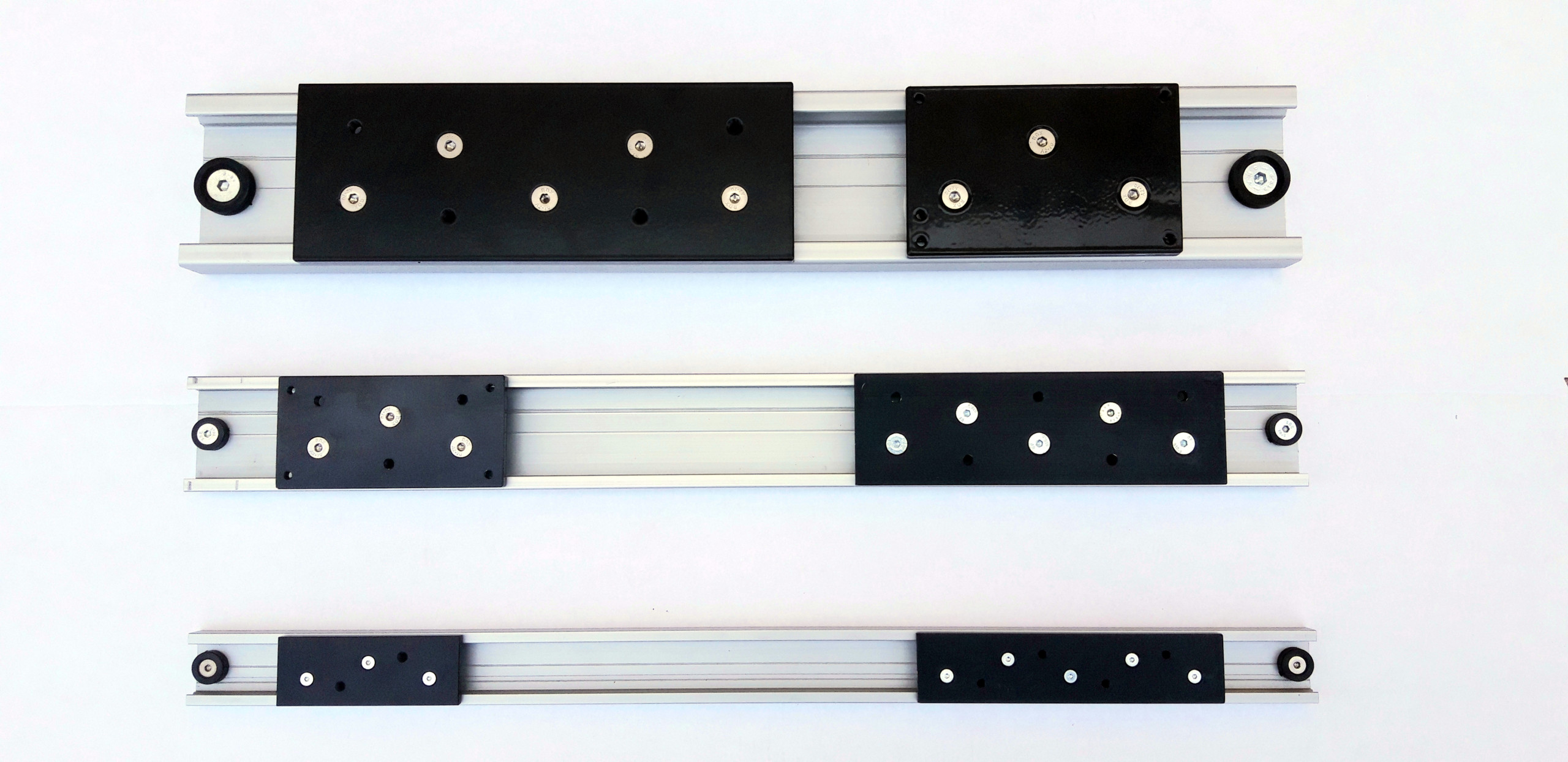

- Linear Motion Systems

-

Machine safety

- Emergency push buttons

- Human Machine Interfaces/Signal lights

- Interlocking Safety Switches with locking

- Ribbon Switches & Safety Bumbers & Mats & Edges

- Rope Safety Switches

- Safety Fences

- Safety interlocking switches/Safety RFID sensors

- Safety Laser Scanners

- Safety Light Curtains

- Safety relays/Programmable safety relays

- Signal lights

- Two-Hands Control Devices

- Machine vision & Code reading

- Motors & Drives

- Power supply solutions

- Rack & Pinion Gears

- Sensors & Measuring devices

- Timing belt applications

- Vacuum technology & grippers