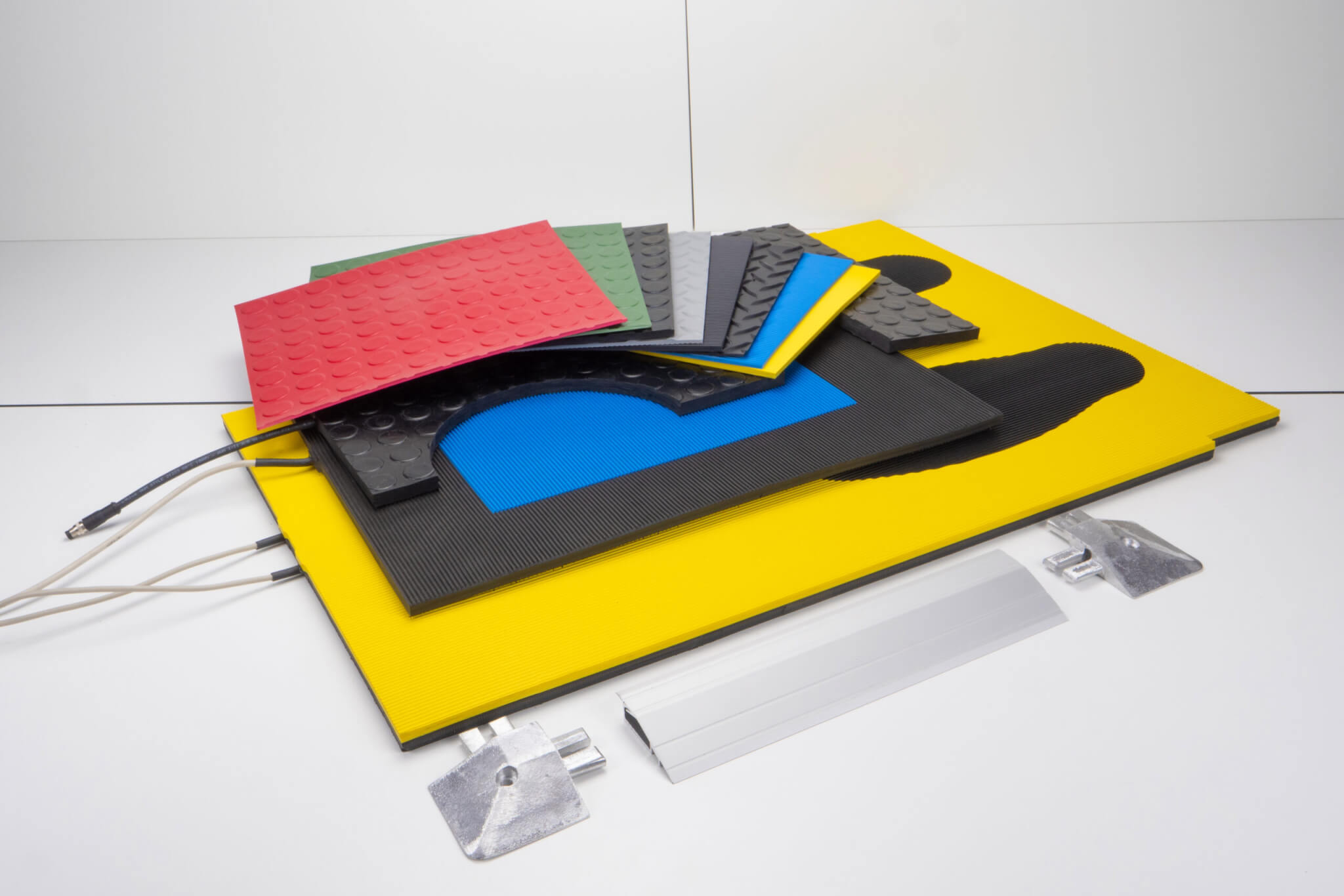

TAPESWITCH safety mats and specialty mats

TAPESWITCH safety mats and specialty mats are available in standard sizes and custom shapes for both safety and sensing applications. The CKP/S1, Armormat, and Diamond Plate mats utilize ribbon switch-based detection, while LMI mats operate with a mechanism involving two steel plates.

CKP/Solo safety mats function like regular safety mats but incorporate a built-in Class 3 safety system that independently monitors mat operation, eliminating the need for a separate safety relay. The Solo system has two potential-free outputs, making it suitable for systems like AS-I.

Features:

- Simple, reliable operation

- Impact-resistant

- IP65 or IP67

- Custom shapes and sizes, including holes, bevels, etc.

- Multiple color options

- Safe 4-wire connection

- Meets EN13849-1 PLd with PRSU/4 safety relay

Tapeswitch Safety Relays

Sensing mats without built-in monitoring require a type-approved safety relay for operation. The PRSU/4 safety relay is designed specifically for use with Tapeswitch safety edges and mats.