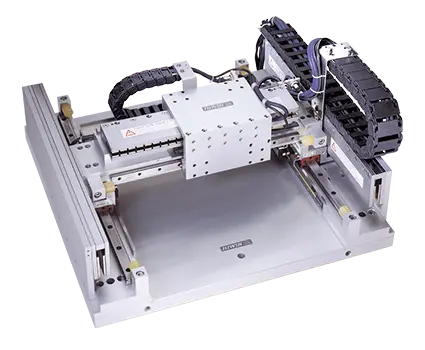

Linear motor systems, gantrys

By combining individual linear axes, various motion platforms can be created — such as gantry systems. A gantry system typically consists of two parallel linear motors supporting and guiding one or more additional linear motors that move across them. Gantries are used in applications that require high performance and precision.

Hiwin gantry systems are primarily manufactured at Hiwin’s own facilities using in-house components, allowing for customization according to customer specifications and delivery as ready-to-use solutions. These systems are suitable for use in cleanrooms, vacuum environments, and settings with variable temperatures.

Key Features:

-

Low inertia

-

Simple assembly

-

Robust aluminum frames

-

Ironless linear motors

-

Precision up to ±1 µm

-

Customer-specific customization available, including granite tables and multi-axis configurations