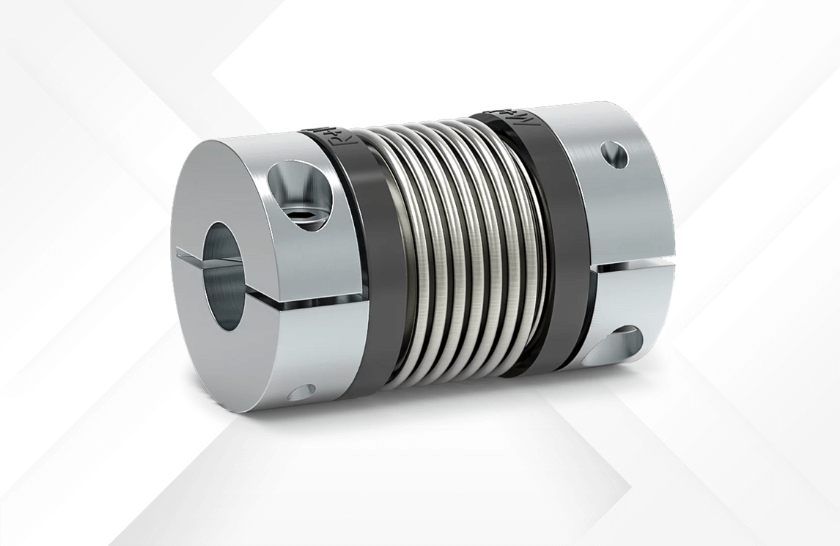

BK Metal Bellows Couplings

High-precision metal bellows couplings are typically used in applications requiring extremely accurate positioning and dynamic motion. Common applications include servo motor drives, medical devices, and more.

Features:

- High precision

- Zero backlash

- High dynamics

- Torque range: 15–10,000 Nm

- Operating temperature range: -30 to 120 °C

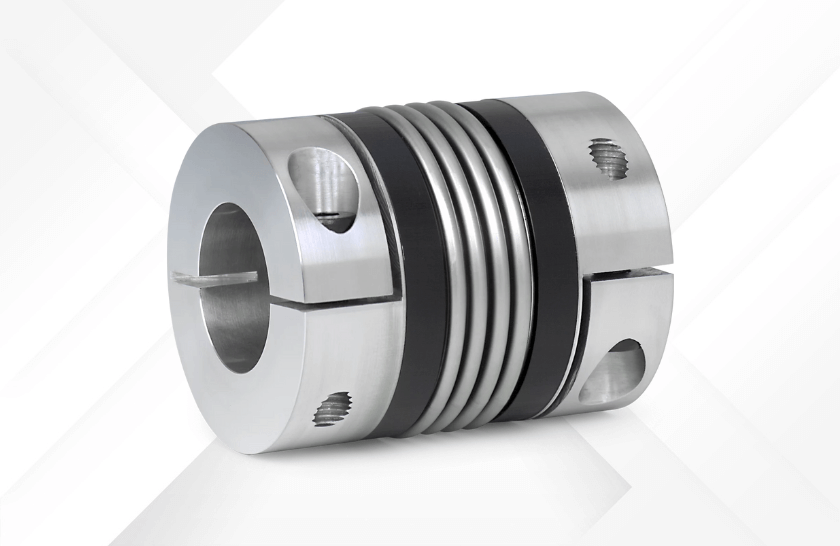

MK Miniature Bellows Couplings

High-precision metal bellows couplings designed for light and ultra-light applications, such as laboratory equipment.

Features:

- High precision

- Zero backlash

- High dynamics

- Torque range: 0.5–10 Nm

- Operating temperature range: -30 to 120 °C

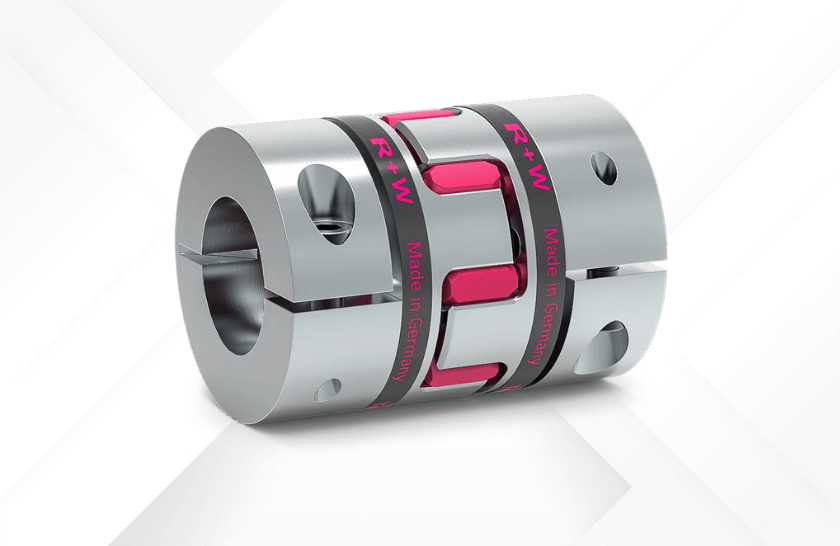

EK Elastomer Couplings

Elastomer couplings are part of the broader category known as jaw couplings. The coupling consists of separate components, namely hubs and an elastomer element positioned between the hubs.

Features:

- High precision

- Zero backlash

- Dampens vibrations

- Easy to install

- Torque range: 0.5–25,000 Nm

- Operating temperature range: -30 to 100 °C

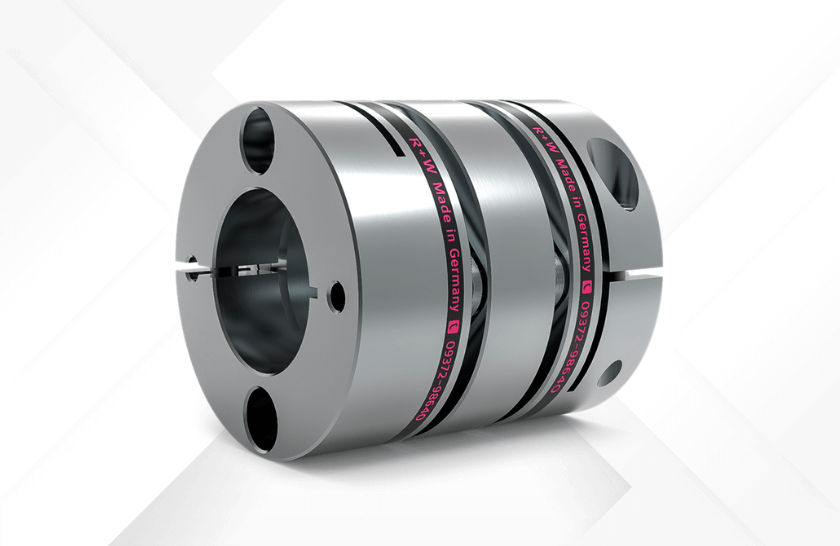

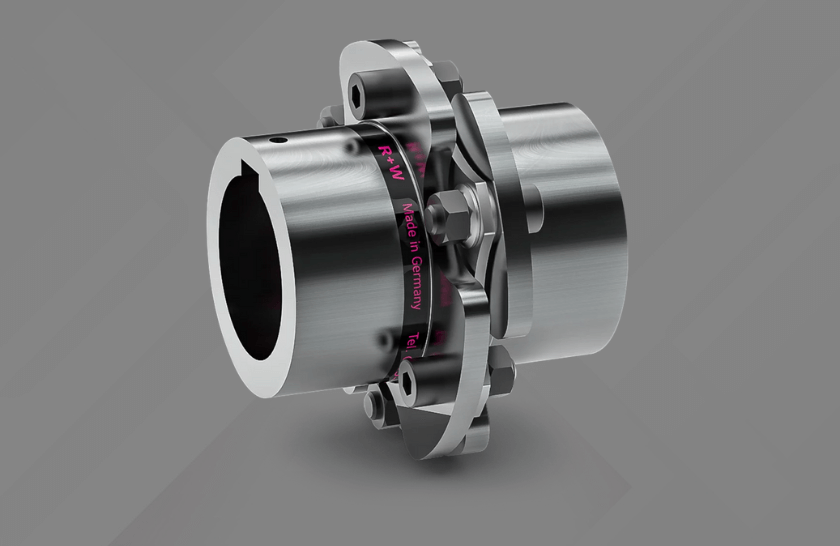

SCL Disc Couplings for Servo Drives

Robust R+W disc couplings transmit torque through a friction-based disc pack, avoiding stress concentrations, backlash, and micro-movements typically caused by shoulder bolts. The design is exceptionally torsionally stiff and durable. R+W disc couplings effectively compensate for shaft misalignments and are ideal for heavy-duty industrial power transmission applications, such as paper machines, steel mills, generators, pulp handling equipment, and compressors.

Features:

- High precision

- Zero backlash

- Extremely torsionally stiff design

- Torque range: 350–50,000 Nm

- Compensation for lateral, axial, and angular shaft misalignments

Disc Couplings Industrial Series

Robust R+W disc couplings transmit torque through a friction-based disc pack, avoiding stress concentrations, backlash, and micro-movements typically caused by shoulder bolts. The design is exceptionally torsionally stiff and durable. R+W disc couplings effectively compensate for shaft misalignments and are ideal for heavy-duty industrial power transmission applications, such as paper machines, steel mills, generators, pulp handling equipment, and compressors.