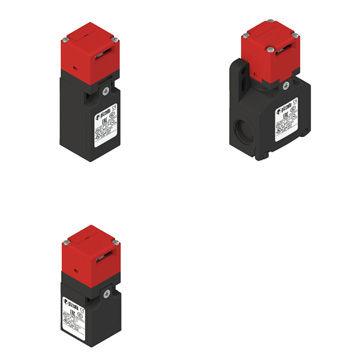

Pizzato FD/FL series safety limit switches

Pizzato FD/FL series safety limit switches are robust, metal-bodied switches available in nine different contact configurations. The basic model includes an M20 cable entry, with additional models available with M12 connector versions. The operating temperature for the standard model is -25…+80 °C, with an extended range version (-T6) available for -40…+80 °C.

Features:

- Metal body with one or three cable entries

- IP67 protection rating

- 9 contact configurations

- 6 different actuator heads

- Also available with M12 connector version

- Option for gold-plated contacts