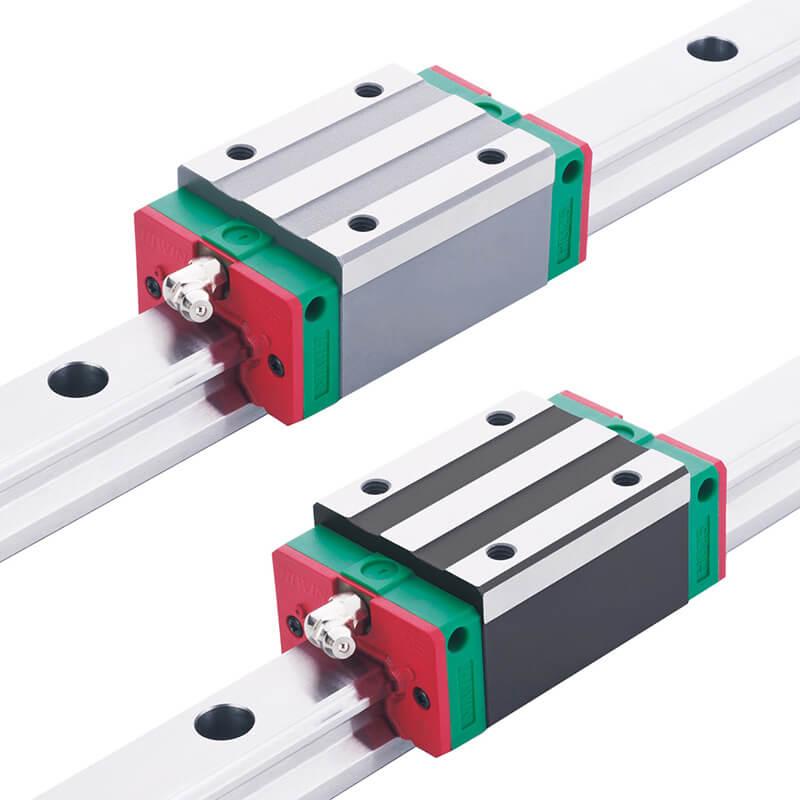

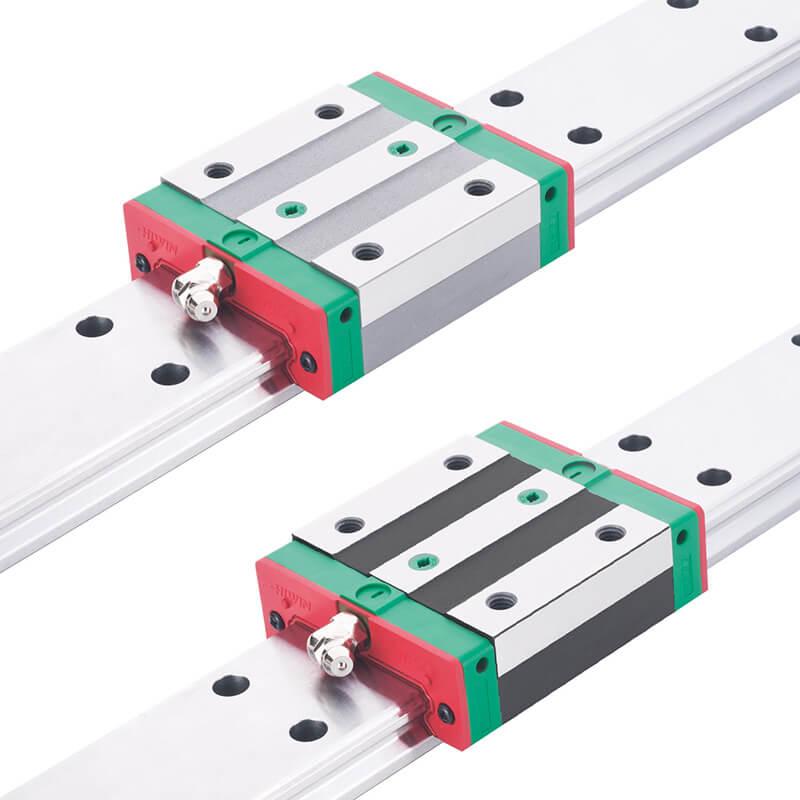

HG series

Standard guideway series, 4-row ball-type linear guideway. Narrow and flanged carriages, stock item.

Features:

- Stock guide sizes 15-65, guide lengths 3,885-4,000 mm

- Narrow guide carriages, HGH..CA/HA, HGL..CA/HA

- Flanged carriages HGW..CC/HC

- Guides cut to size, with ground ends and extended into a track

- Wide range of accessories available

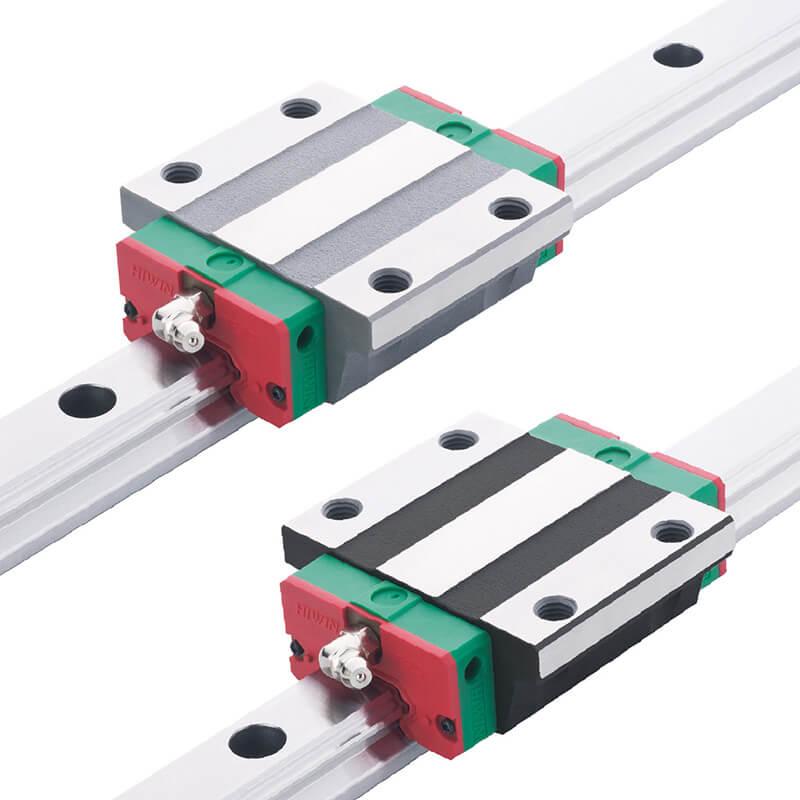

QH/QE series

Ball chain guideway series, 4-row ball-type linear guideway. Narrow and flanged carriages, partially in stock.

Features:

– Stock guide sizes QH15-45 and EQ15-35, guide lengths 4,000 mm

– Narrow guide carriages, QHH..CA/HA, QEH..SA/CA

– Flanged carriages GHW..CC/HC, QEW..SC/CC

– Guides cut to size, with ground ends and extended into a track

– Wide range of accessories available

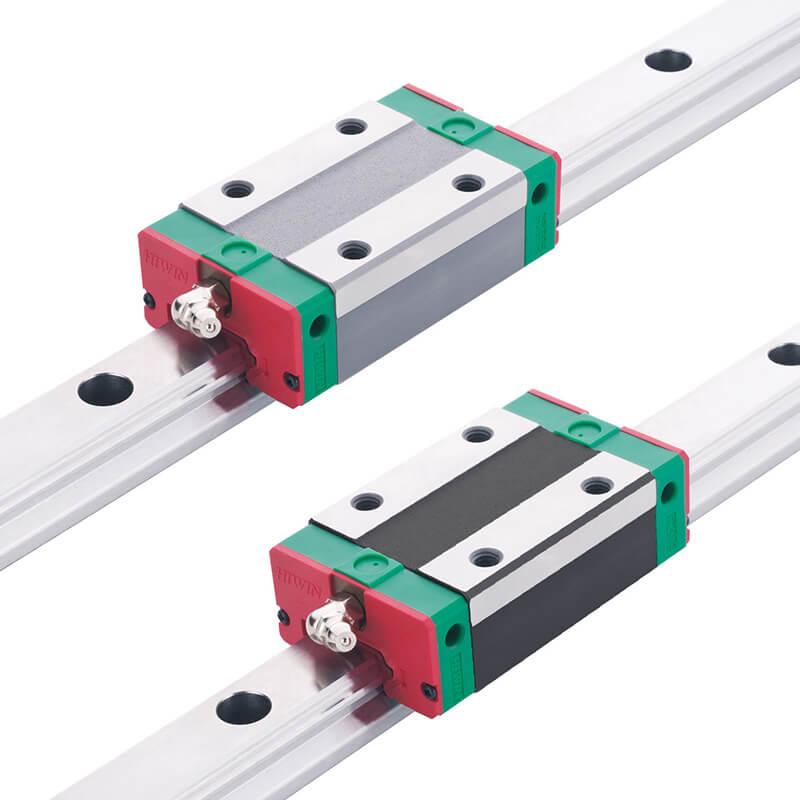

EG series

Low-profile linear guideway series, 4-row ball-type linear guideway. Narrow and flanged carriages, partially in stock.

Features:

- Stock guide sizes 15-30, also available in size 35, guide lengths 3,960-4,000 mm

- Narrow guide carriages, EGH..SA/CA

- Flanged carriages EGW..SC/CC

- Guides cut to size, with ground ends and extended into a track

- Wide range of accessories available

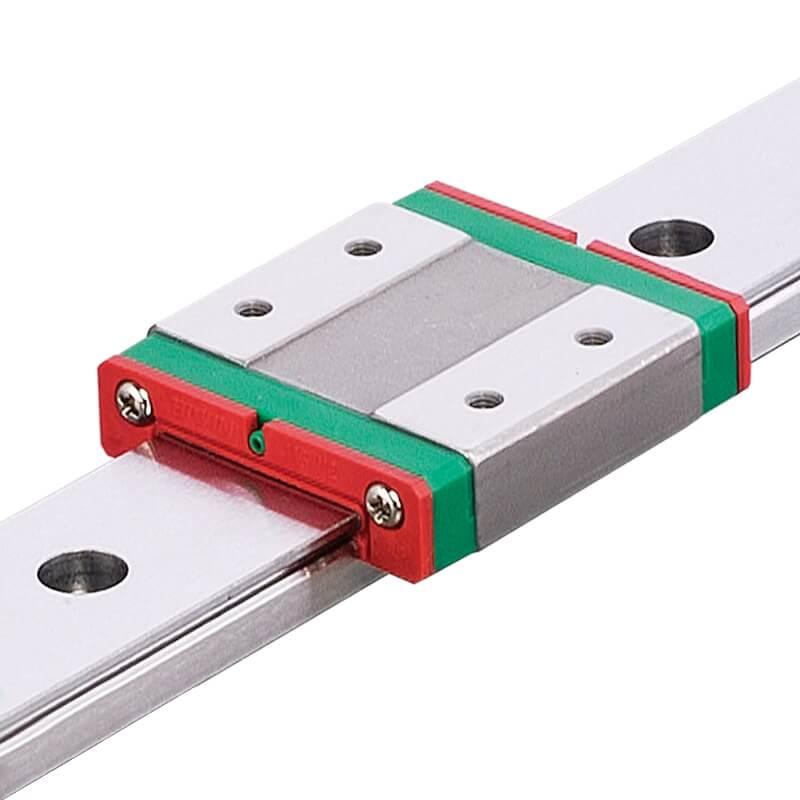

MG series

Miniature guideway series, 2-row ball-type linear guideway. Narrow standard and long carriages, stock item.

Features:

- Stock guide sizes 7-15, guide lengths 600-2,000 mm

- Standard guide carriages, MGN..C and MGW..C

- Long guide carriages, MGN..H and MGW..H

- Guides cut to size, with ground ends and extended into a track

- Wide range of accessories available

WE/QW series

Wide, 4-row ball-type linear guideway. Narrow and flanged carriages, made-to-order item.

Features:

- Made-to-order, also available with ball chain (QW)

- Narrow guide carriages, WEH..CA / QWH..CA

- Flanged carriages, WEW..CC / QWW..CC

- Guides cut to size, with ground ends and extended into a track

- Wide range of accessories available